There are two main types of copper deposit: sulphide (suchas as those mined for centuries in Cyprus) and porphyry (such as those are prevalent in Chile). Sulphide deposits are normally of relatively high grade (4 to 20 percent copper), but restricted in volume, whereas the relatively lower grade (0.4 to 1 percent copper) porphyry deposits are extremely voluminous. Both can be mined underground or in open pits and may yield other metals as by-products, such as gold, molybdenum and silver in the case of porphyry deposits.

Chile produces mainly copper concentrate, a powder produced by means of a flotation system (crushing, milling and concentrating the primary material), which typically contains 30 percent of copper. Chile produces 1,400,000 tons of waste daily as a result of copper production. Whilst these toxic residues remain in the landscape where copper is being extracted, the primary material is shipped to industrial centres where it is transformed into blisters, a more concentrated intermediate material.

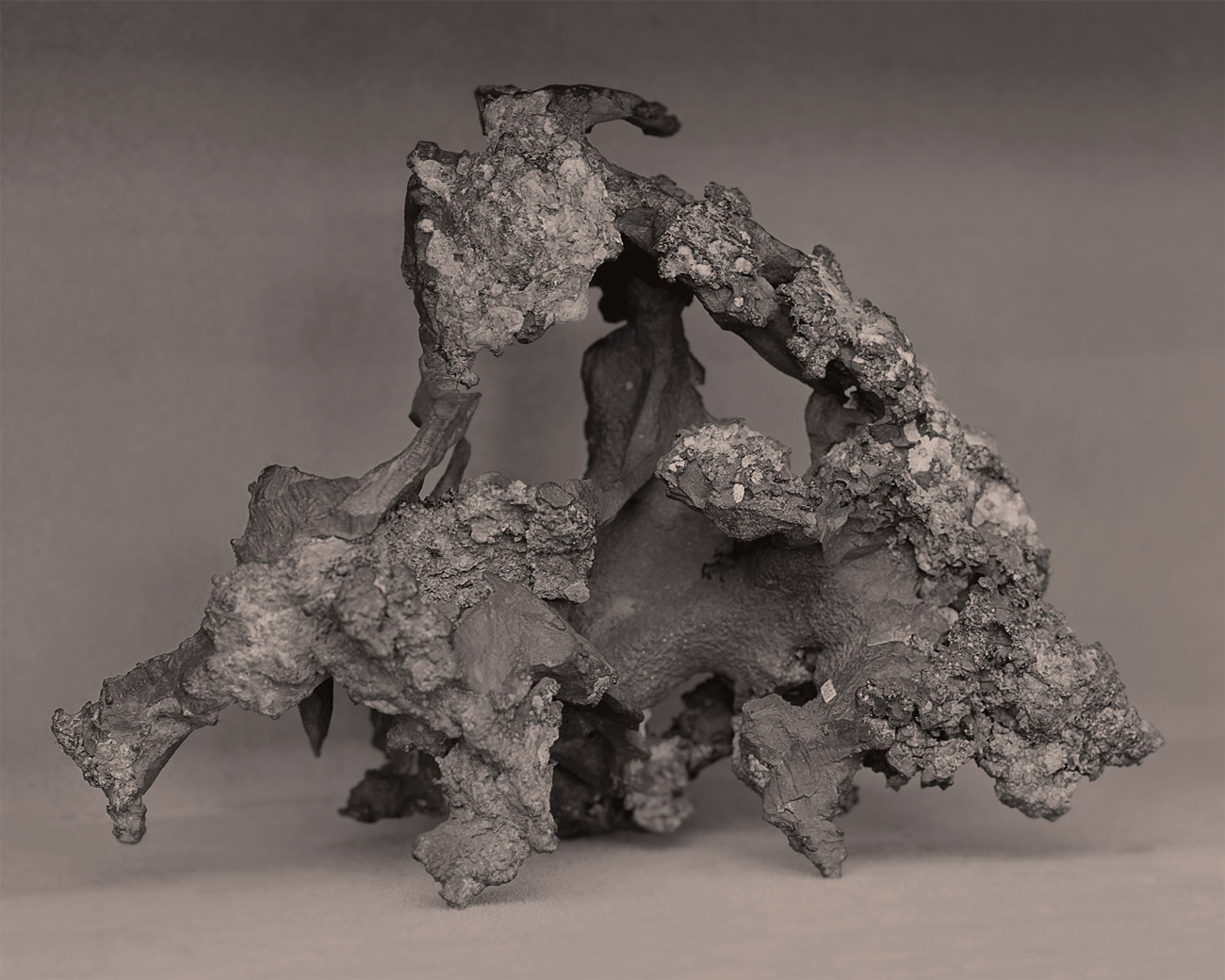

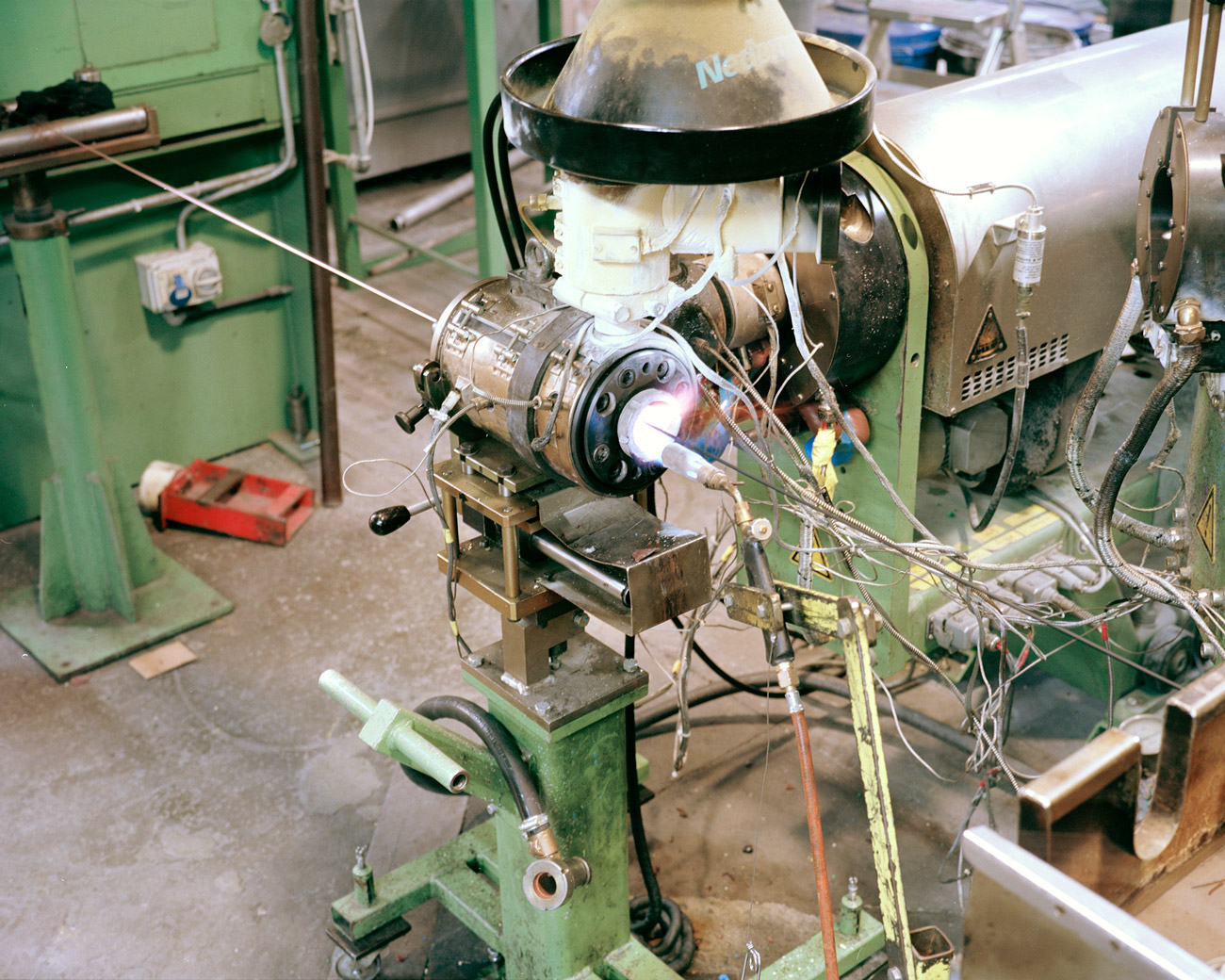

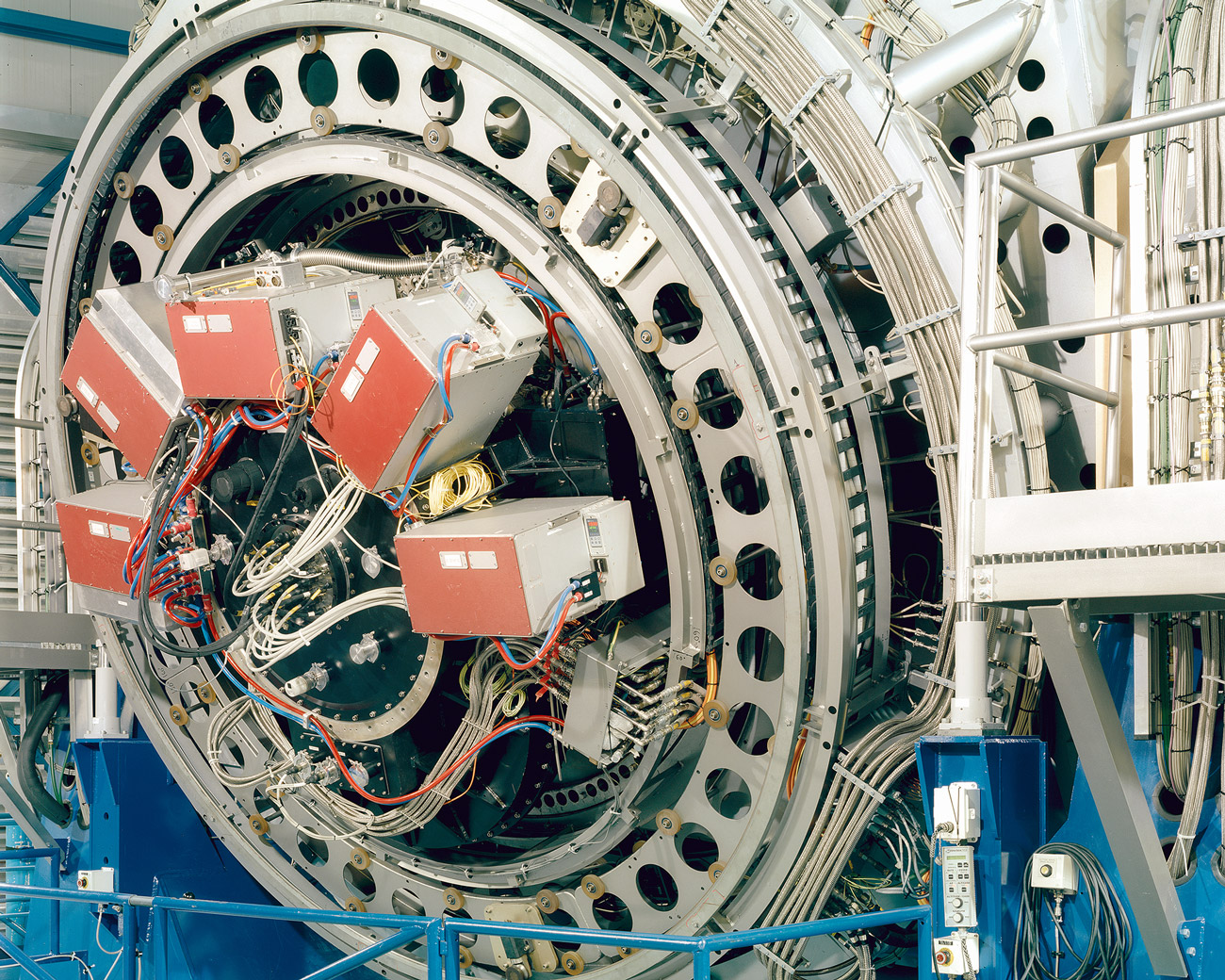

Copper blisters are stored in warehouses around the world, where they can be exchanged up to forty times before their final delivery. These intangible transactions take place through centres for metal trading, such as the London Metal Exchange, through future contracts, agreements made to buy or sell a fixed amount of metal on a fixed future date at a price agreed today. The ‘blisters’ are melted down and mixed with other sources of copper, including recycled materials, forming ‘anodes’ that are transformed into cathodes and then into rods – the basic component for the production of cables for the energy and telecommunications industries. Smelted copper returns to Chile hidden within manufactured goods, perpetuating a circle of mobility that began with the extraction of the ore.